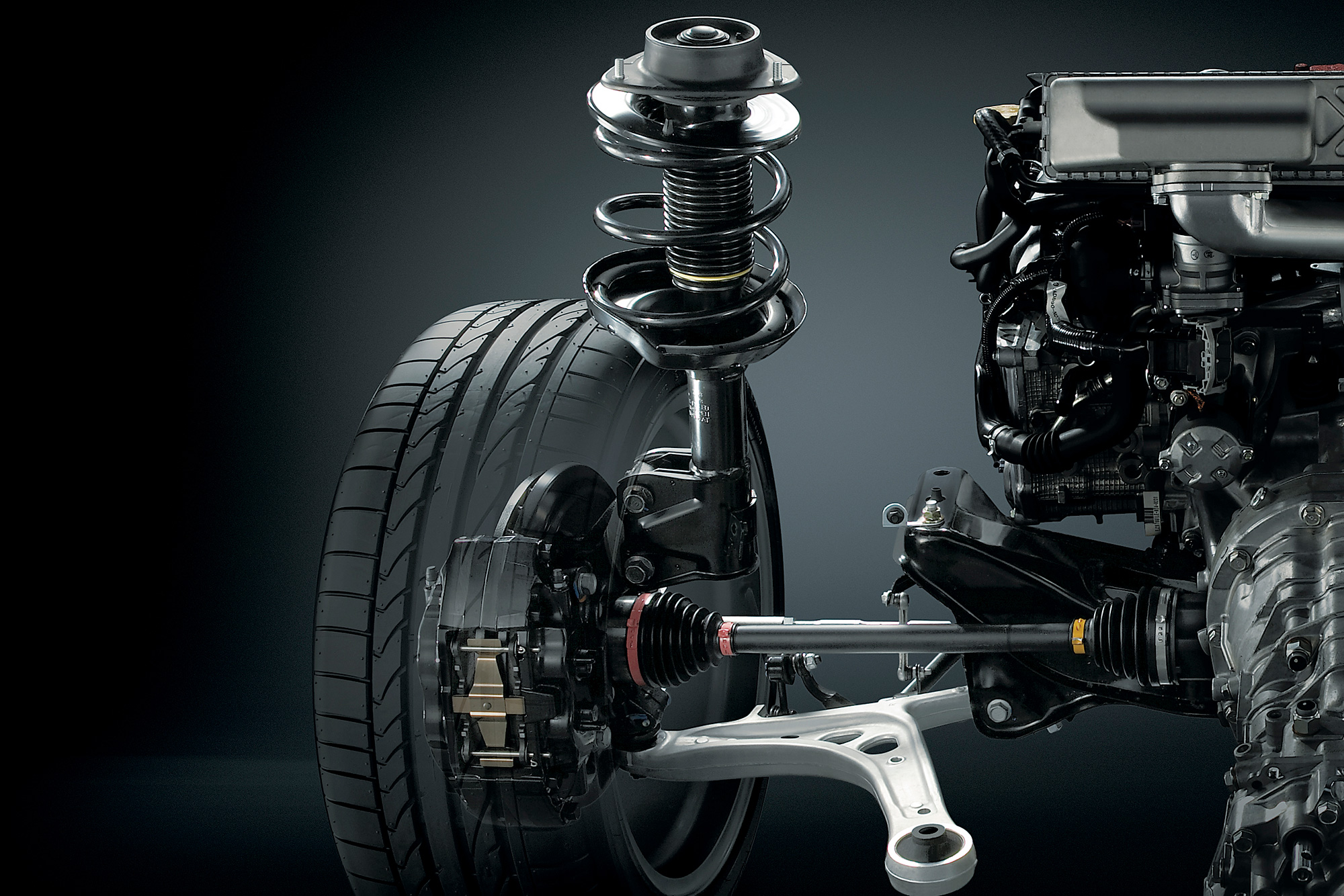

ETA Rubber Strengthens with New Tensile Testing Equipment.

ETA Rubber is taking innovative steps in the field of tensile testing equipment to enhance quality and improve efficiency in the production process. The utilization of tensile testing equipment aims to elevate quality standards. This initiative not only enhances the durability and performance of products but also strengthens ETA’s competitiveness in the rubber industry.